Intel has a large operation in the US, particularly in Oregon and Arizona. I recently visited Arizona for Intel Tech Tour 2025, where Intel made several exciting announcements at its huge Ocotillo facility.

I recently toured the campus and was especially impressed by Fab 52, Intel’s newest and biggest facility. It’s equipped with the most advanced chip-making technology available and will be used to create Intel’s next generation of processors using the 18A process.

Intel has high hopes for 2026, particularly with the potential of its new Fab 52 facility. Here’s an overview of their 18A technology, along with a firsthand look inside the remarkable Fab 52.

The heart of Intel Panther Lake is 18A

I recently analyzed Intel’s upcoming Panther Lake mobile processors and detailed the new Intel Arc graphics that will work with them. I didn’t go into much detail about Intel 18A, but it’s a key technology, and I want to explain why.

A key way to track advances in chipmaking is by looking at the size of transistors, which are measured in nanometers. Smaller transistors mean more can fit on a chip. And more transistors generally lead to faster and more efficient performance.

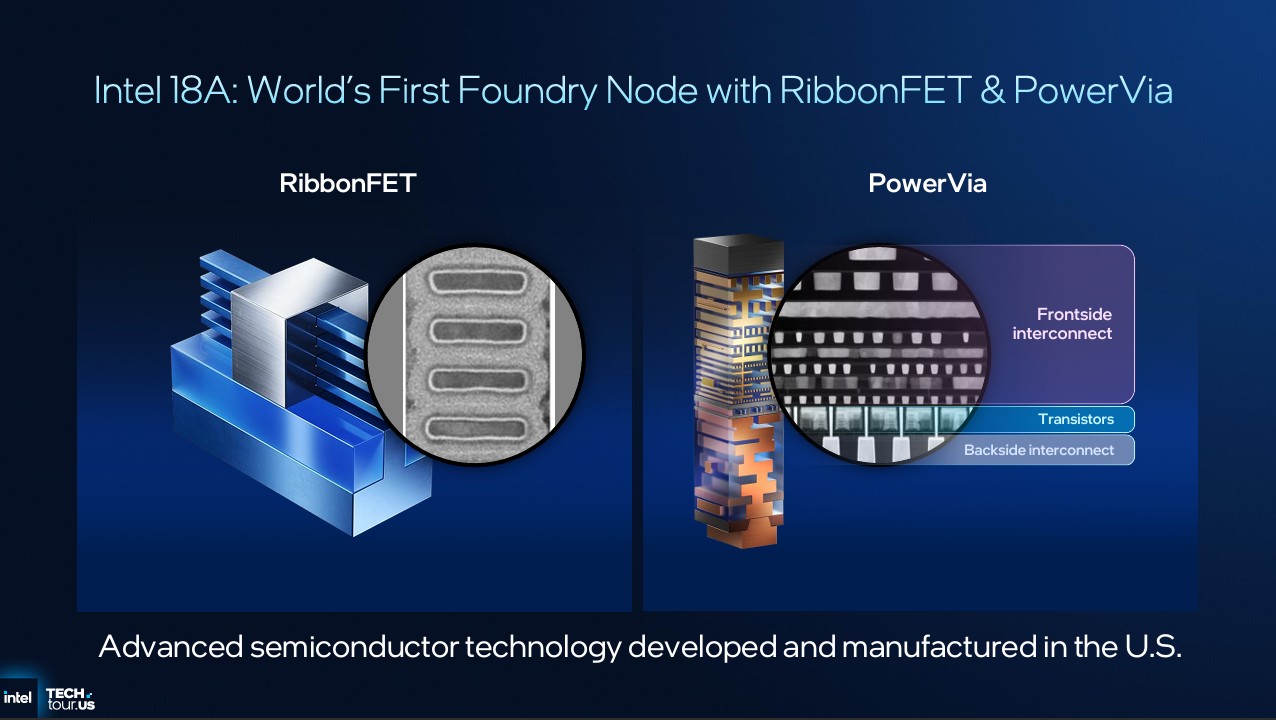

Intel 18A is a next-generation chip technology, representing the most advanced manufacturing processes currently available. What sets it apart is that it’s the first to incorporate two new key innovations – RibbonFET and PowerVia – into chips that will be available to everyday consumers.

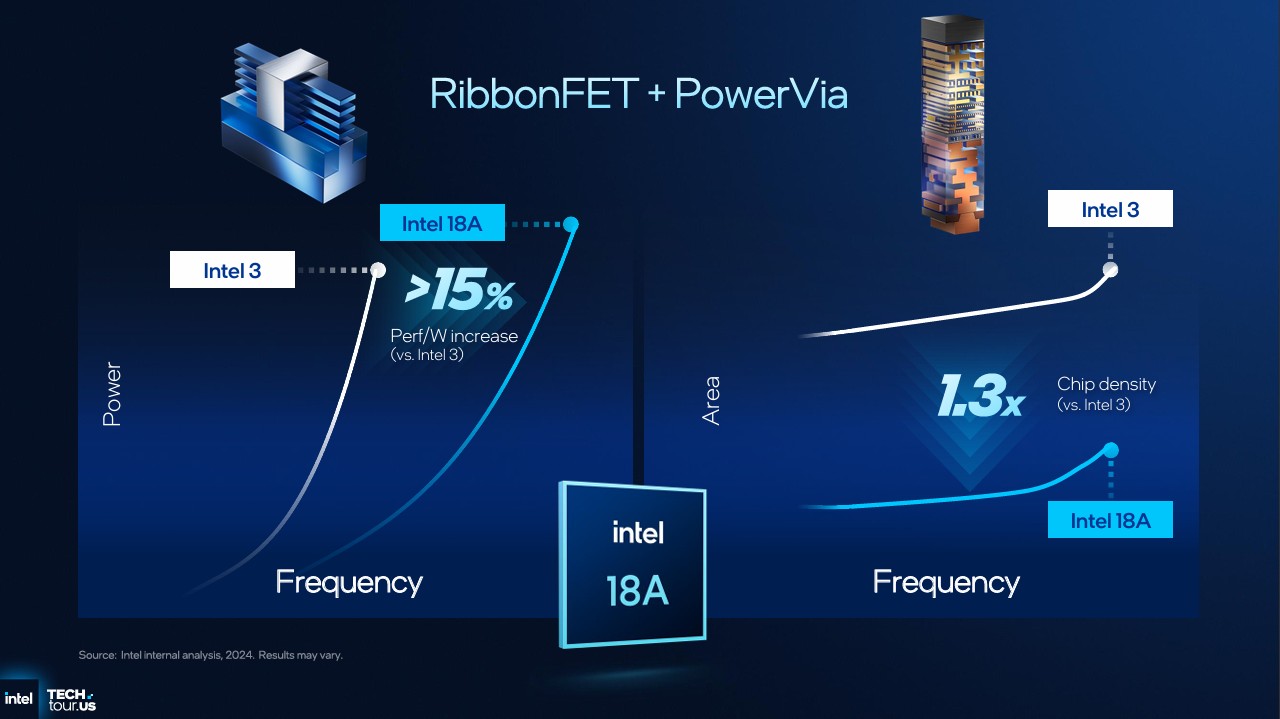

The current standard in transistor design, FinFET, is being replaced by RibbonFET. FinFET uses fin-shaped transistors with a gate on top, while RibbonFET employs a new, more adaptable “ribbon” design with a gate that completely surrounds the transistor. This new approach offers better control over electricity flow, reduces power waste, improves performance and efficiency, and allows for more transistors to be packed into a smaller space.

RibbonFET and PowerVia represent major breakthroughs in processor manufacturing, not just typical annual upgrades. They change the very foundation of how processors are built.

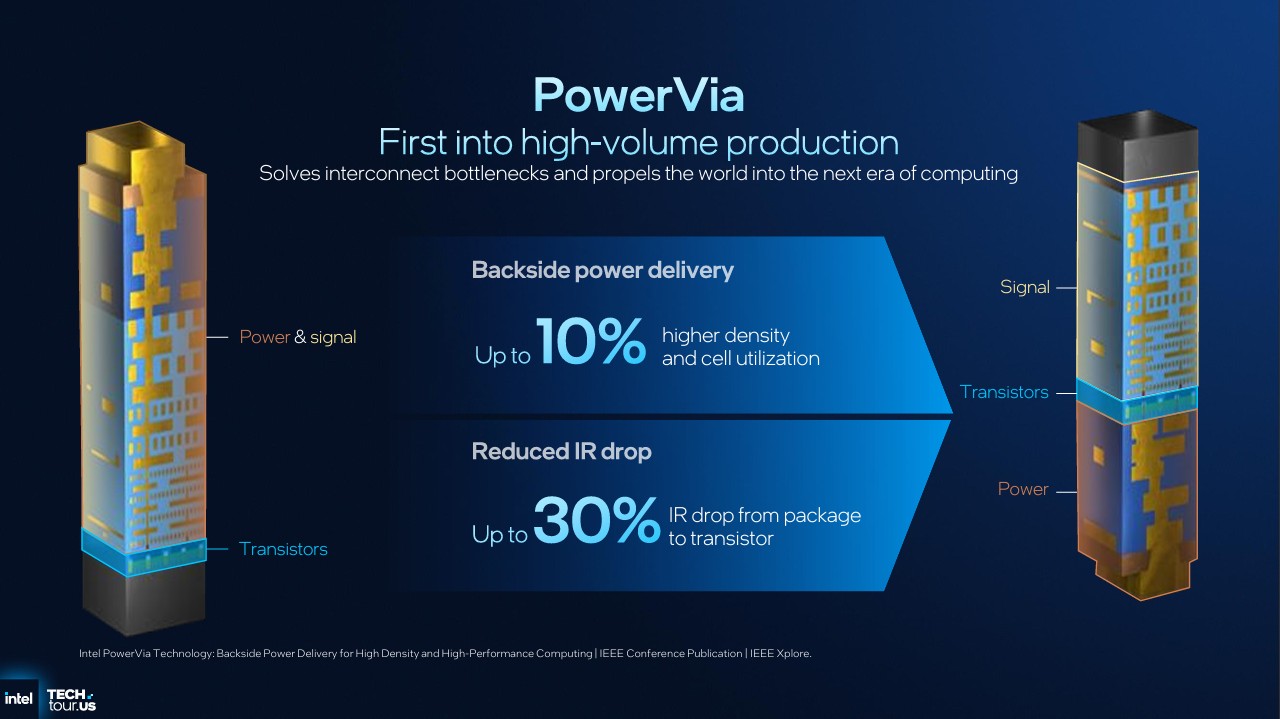

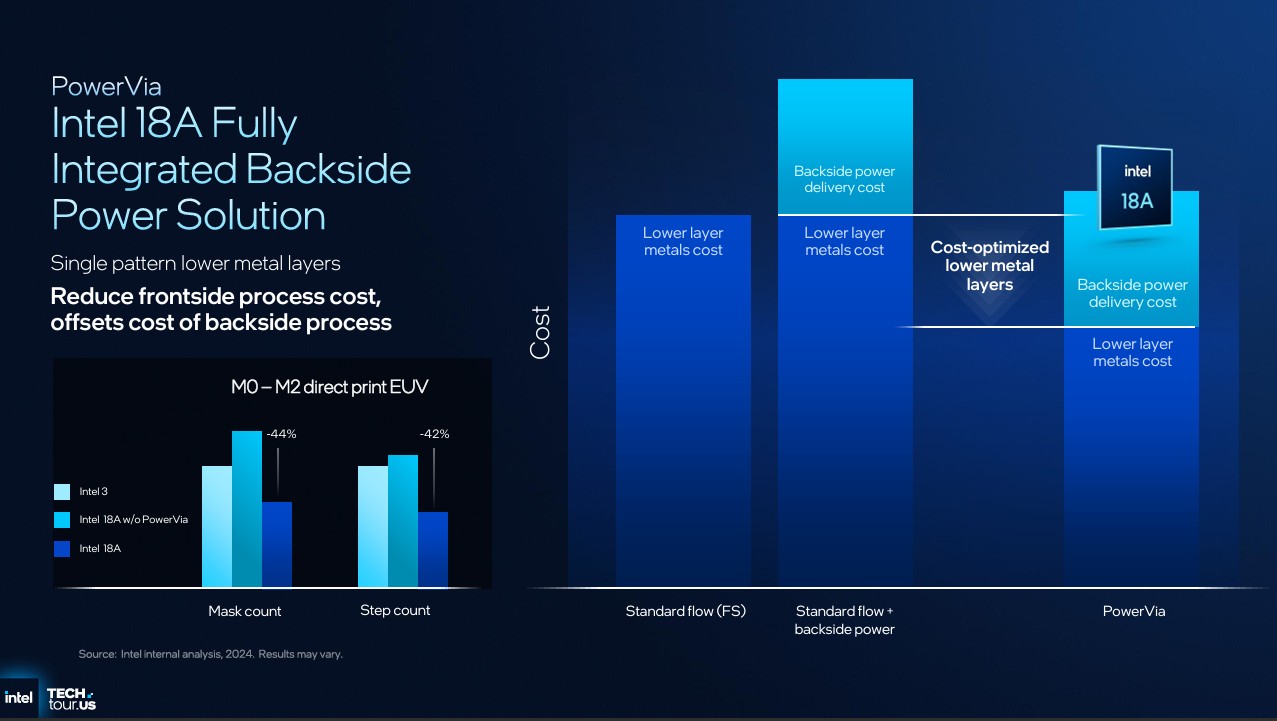

PowerVia is a significant step forward in chip technology. Traditionally, both power and signals were routed through the front of a chip, which could cause bottlenecks and slow performance as chips became more crowded. Intel’s 18A process now allows power to be delivered through the back of the chip, freeing up the front side for faster signal processing.

As a researcher, I’ve found that combining these two technologies leads to a real boost in performance, efficiency, and reliability, especially when dealing with demanding tasks like artificial intelligence. What’s particularly exciting is Intel’s 18A process can work alongside other Intel processors. This is made possible by their Foveros-3D packaging, which allows us to stack different chip components on top of each other, creating a more versatile and powerful system.

Intel’s new Panther Lake platform is the first to be made using the advanced Intel 18A process, unlocking its full potential. As production increases, other companies may start relying on Intel for their chip manufacturing, and all of this is happening at Intel’s Fab 52 facility.

Fab 52 is alive, and I went aside to see what it’s all about

Intel’s Ocotillo campus is incredibly large. It has been expanding since the 1990s and now covers more than a square mile. The site even includes its own water treatment and recycling facility, and the newest building, Fab 52, is particularly big – even for this huge campus.

Building the facility took four years, involved thousands of workers, and cost tens of billions of dollars. The construction required massive excavation – enough soil and rock to fill more than 400 Olympic-sized swimming pools. Over 600,000 cubic meters of concrete were used, so much that Intel actually built a concrete mixing plant right at the site. This concrete was reinforced with over 75,000 tons of steel.

Intel’s new facility wasn’t simply about building a large structure. A major challenge was preparing the ground to support the incredibly heavy Extreme Ultraviolet Lithography (EUV) machines needed for their 18A technology. These machines are so massive that it takes three Boeing 747 cargo planes to deliver just one, and the facility utilizes special, built-in cranes in the ceiling to help with both construction and ongoing maintenance.

I was able to see the EUV machines firsthand, but getting inside wasn’t simple. First, I had to leave all electronics – phones included – outside, because even wireless signals could disrupt the incredibly sensitive equipment. Then, I had to put on a hairnet, gloves, and shoe covers before being allowed into the clean room. Once inside, I was fully covered in a protective suit, including a hood, boots, goggles, and another pair of gloves.

Creating semiconductors requires top-level expertise in engineering, chemistry, and materials science, combined with remarkable planning and anticipation.

Stepping into the chip factory, you’ll immediately notice how carefully controlled the environment is. Intel precisely manages the temperature, humidity, and air composition. Powerful systems constantly filter the air – cycling it six times every minute – making it far cleaner than a typical hospital operating room. You might also notice the unusual yellow-green lighting, which is used to shield the chips from certain types of light, much like a darkroom protects photographic film.

I was amazed by the vast network of overhead tracks – seemingly stretching for miles – where hundreds of robots move materials between machines and buildings. The facility was filled with incredibly sophisticated equipment, and it was clear it was always being renovated and improved, both inside and out. Intel carefully evaluates which tools to update or replace every day, making sure everything within the facility contributes to the overall process.

I honestly have no idea how we figured out how to make rocks think, but working at Intel in Arizona really taught me a ton about how chips are made. I’m super excited to see how good the new Panther Lake processors turn out, especially now that I’ve actually seen the factory where they’re built!

Stay up-to-date with the latest news, insights, and features from Windows Central by following us on Google News!

Read More

- How to Get the Bloodfeather Set in Enshrouded

- Every Targaryen Death in Game of Thrones, House of the Dragon & AKOTSK, Ranked

- 4 TV Shows To Watch While You Wait for Wednesday Season 3

- The Pitt Season 2, Episode 7 Recap: Abbot’s Return To PTMC Shakes Things Up

- Gold Rate Forecast

- One of the Best EA Games Ever Is Now Less Than $2 for a Limited Time

- Goat 2 Release Date Estimate, News & Updates

- Best Controller Settings for ARC Raiders

- Best Werewolf Movies (October 2025)

- 10 Movies That Were Secretly Sequels

2025-10-09 16:16